Request for Callback

Fill out this form to download.

Discover the top ERP for the manufacturing industry, offering robust solutions tailored to improve operations. Maximize efficiency with cloud-based ERP systems designed for manufacturing companies.

7,436+

Valued Clients

95%

Client Retention

90%

Tax Calculation

97%

Client Satisfaction

Transform Your Manufacturing Business with Right ERP System

Enterprise Resource Planning (ERP) solutions are essential for modern manufacturing businesses to optimize operations, enhance efficiency, and streamline processes. The right ERP system provides seamless integration across all functional areas, from production planning to supply chain management.

Thank you for your interest in Expand smERP. Our team will reach out to you soon to schedule your personalized demo.

Book Your Free Demo Now!

Fill out this form to know your offer.

ERP manufacturing software is a comprehensive, scalable, and customizable enterprise manufacturing software system that offers a transformation for the manufacturing industry from traditional software. Top erp systems offers a solution that enables manufacturing companies to compete in the prevailing market. Better management of your manufacturing processes transforms the supply chain to achieve a production plan with your sales plan, finance, and customers.

An ERP for manufacturing industry provides a centralized platform for managing all the core business functions, including accounting, sales, procurement, and human resources.

A cloud-based erp system is specifically tailored to meet the unique needs of the manufacturing industry. A robust erp software helps provide real-time visibility into operations, enabling you to track and analyze data from different departments and make informed decisions to improve the efficiency, productivity, and profitability of your business.

The manufacturing industry faces numerous challenges, from supply chain disruptions to increasing production costs. Businesses must adapt to evolving market demands, implement efficient processes, and leverage technology to stay competitive.

The ongoing pandemic has brought attention to the weakness of international supply systems. Manufacturers will need to implement best practices in the process to reduce risks and ensure a continuous supply of raw materials and components.

Manufacturers are now facing fierce competition from both domestic and international companies as a result of globalization. To remain competitive, they must constantly innovate, enhance product quality, and optimize manufacturing procedures.

Automation, artificial intelligence (AI), Internet of Things (IoT), and other Industry technologies are rapidly changing the production scene. Manufacturers must quickly adapt to these new technologies or risk falling behind their competitors.

There is a growing demand for skilled workforce who are knowledgeable about advanced industrial processes. However, such skills are in short supply.

Manufacturers are expected to meet higher laws and sustainability standards as the emphasis on environmental sustainability grows.

The manufacturing industry has undergone a huge transformation in the last few years. The way it does business and performs operations has changed entirely. Manufacturers have learned the importance of smooth information flow, which is necessary for the effective functioning of a business. An increasing number of manufacturers in India are implementing the latest and sophisticated manufacturing ERP software and ERP solutions to foster better collaboration among their employees.

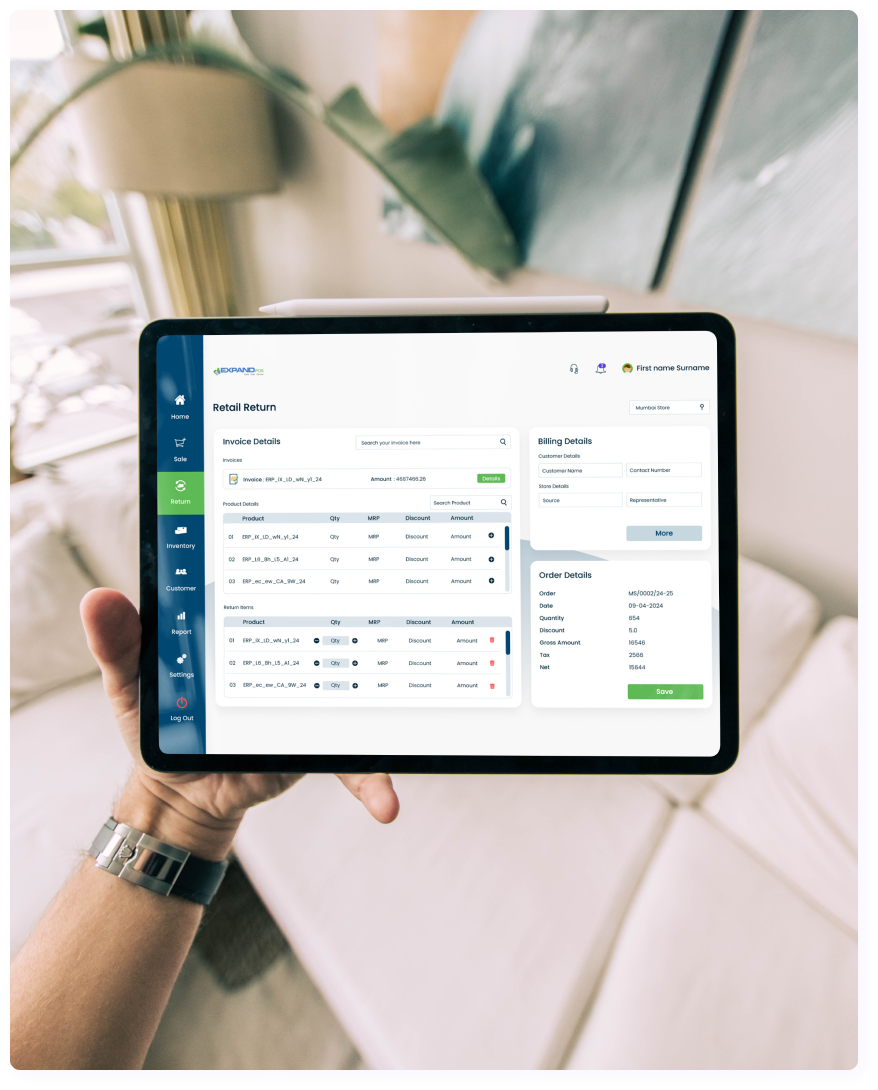

Are you aware of the use of ERP for manufacturing in production management? An ERP system for production is a critical enterprise software used by businesses to manage and streamline their production processes. It helps them keep track of inventory, orders, production scheduling, and even employee time and attendance. By using robust manufacturing management software like Expand ERP, you can increase your employees' working efficiency, reduce waste, and save time and money. It's like having a super-powered assistant that can organize and automate everything for you.

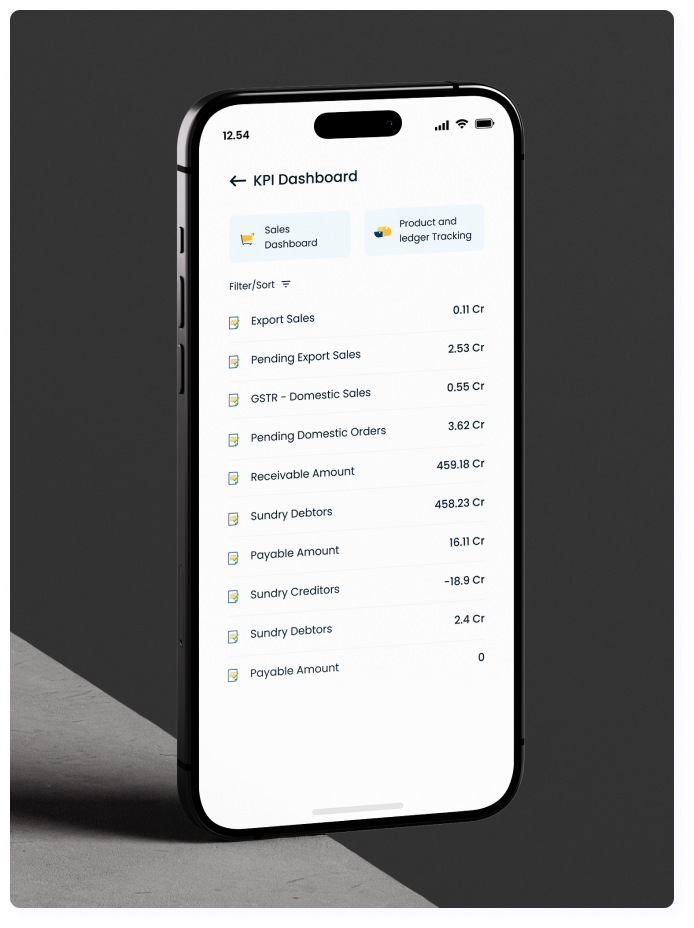

With Expand ERP, you can improve your manufacturing operations, increase your profits, and stay ahead of the competition. It provides 360-degree visibility into your business and also helps you make data-driven decisions to grow your business. Sounds interesting, right?

Expand ERP software is a game-changer and the leading ERP software for manufacturing in India. It offers numerous benefits of manufacturing erp software solutions that help businesses operate more efficiently and effectively.

One of the key benefits of this integrated manufacturing erp software is improved visibility into critical business data. Expand ERP Gives detailed production flow management and a quick single entry option to capture the input, output, excess consumption, wastage, and gain/loss. Our software is cloud-based platform for manufacturing management that allows tracking production progress and easily makes changes to increase production efficiency and reduce costs. It gives you a clear picture of accurate account quotes with a single click. Expand ERP allows making an informed decision and responding quickly to changing market conditions by providing real-time insights into various business operations.

It also eliminates the need for multiple systems that don’t perform effective communication. This cloud software for manufacturing automates and optimizes your core business process. The best part of using a standard ERP software is it can reduce the risk of errors and increase the productivity rate. With all these benefits come overall cost reductions and efficiency which leads to the growth of a business.

Manage production flow ⇒ inventory control ⇒ increase production efficiency ⇒ low cost = business growth.

The manufacturing sector needs to address several key strategic issues if they want to successfully compete in this dynamically changing business environment. A common strategy used by organizations for achieving this goal is just-in-time and quality improvement programs. Cloud-based ERP for manufacturing is designed to address the problem of a breakup of information in manufacturing and supply chain organizations. Best ERP for manufacturing regulates the entire business strategies with a suite of ERP software solutions in all areas of business.

Moreover, modern ERP solutions are used as a desirable link to improve integration between all functional areas within the manufacturing enterprise, including production planning in ERP and management software for optimizing processes.

Manufacturing is a complex industry that requires a high level of organization and coordination between different departments and stakeholders. This is where top manufacturing erp systems come in as an essential tool to help manufacturers manage their operations more efficiently. By implementing the strong ERP software for manufacturing, you can streamline your business process, and improve communication between different departments, which always results in increased productivity and profitability.

ERP manufacturing cloud software solutions also provide real-time insights into critical business data that can help you to make informed decisions and respond quickly to changing market conditions. These manufacturing software applications let you automate various manual tasks, such as data entry and inventory management, and also reduce the risk of errors. It can save valuable time for employees to focus on more important tasks.

Therefore, the ERP system in manufacturing company is an indispensable tool that offers numerous benefits and helps manufacturers stay competitive and thrive in today's fast-paced business environment.

ERP software for manufacturing is designed to cater to the needs of a wide range of businesses involved in the manufacturing industry. It is ideal for small, medium, and large enterprises that need to manage various manufacturing processes, including production planning, inventory management, supply chain management, quality control, and more.

This is the best manufacturing software that can be utilized in various industries. Its specific features and capabilities can help any organization manage, automate, and track every step of its manufacturing process.

When the existing business system is no longer working efficiently.

When the existing system doesn’t support the growth of your business.

If the manufacturing company needs to collect and report on a large amount of data timely.

When it lacks current security requirements to reduce risks.

If the manufacturing company has multiple sites or operates internationally.

When it comes to managing operations in a manufacturing setting, selecting the right Enterprise Resource Planning (ERP) system can make all the difference. The erp systems for the manufacturing industry in India supports the ability to adapt itself to the latest changes enabling a competitive advantage. Let’s explore some of the top ERP solution for manufacturing industry and compare their features and benefits.

An on-premise ERP system is manufacturing operations software that is installed and runs on a company's servers and infrastructure. This means that the company is responsible for managing and maintaining the hardware and software, as well as ensuring that the system is secure and up to date. On-premise ERP systems are generally more customizable than cloud-based systems, but they require more IT resources and can be more expensive to set up and maintain.

Cloud-based ERP for manufacturing systems is generally more flexible and scalable than on-premise systems, as they can be accessed from anywhere with an internet connection and are typically offered on a subscription basis. However, they may not be as customizable as on-premise systems and may require a reliable internet connection for optimal performance.

A hybrid ERP system offers a combination of both on-premise and cloud-based systems. It allows companies to choose which processes and data are kept on-premise and which are hosted in the cloud, based on their specific needs and requirements. This allows companies to take advantage of the customization and control offered by on-premise systems, while also benefiting from the flexibility and scalability of cloud-based systems.

Boost efficiency, reduce costs, and streamline your production with the best ERP for the manufacturing industry. Take control of your operations with real-time insights and automation.

Get Free Demo!

Control PPC

This module helps manufacturers plan and schedule production efficiently.

Financial Management

It provides tools for managing financial operations.

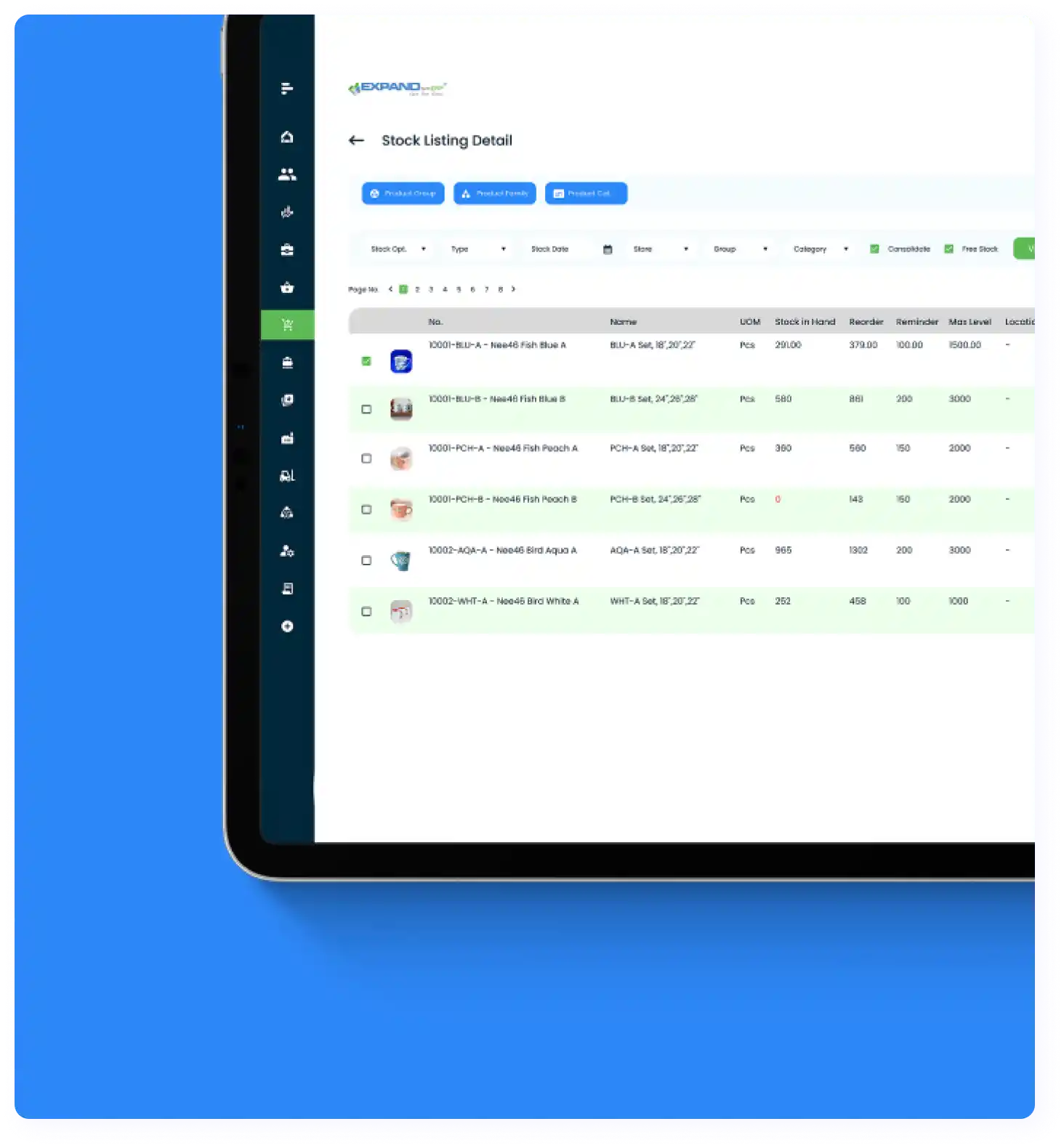

Inventory Management

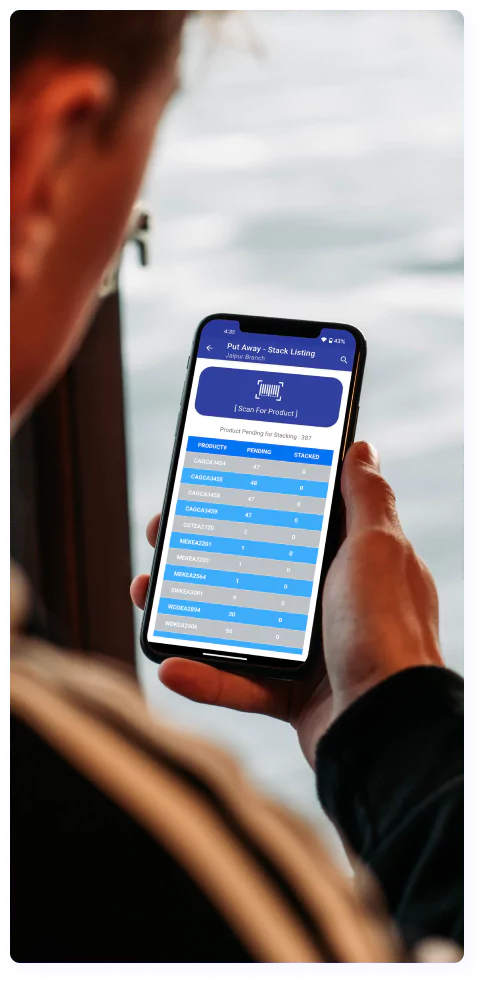

This ERP manufacturing module enables manufacturers to track inventory levels, manage stock movements, and automate reorder points.

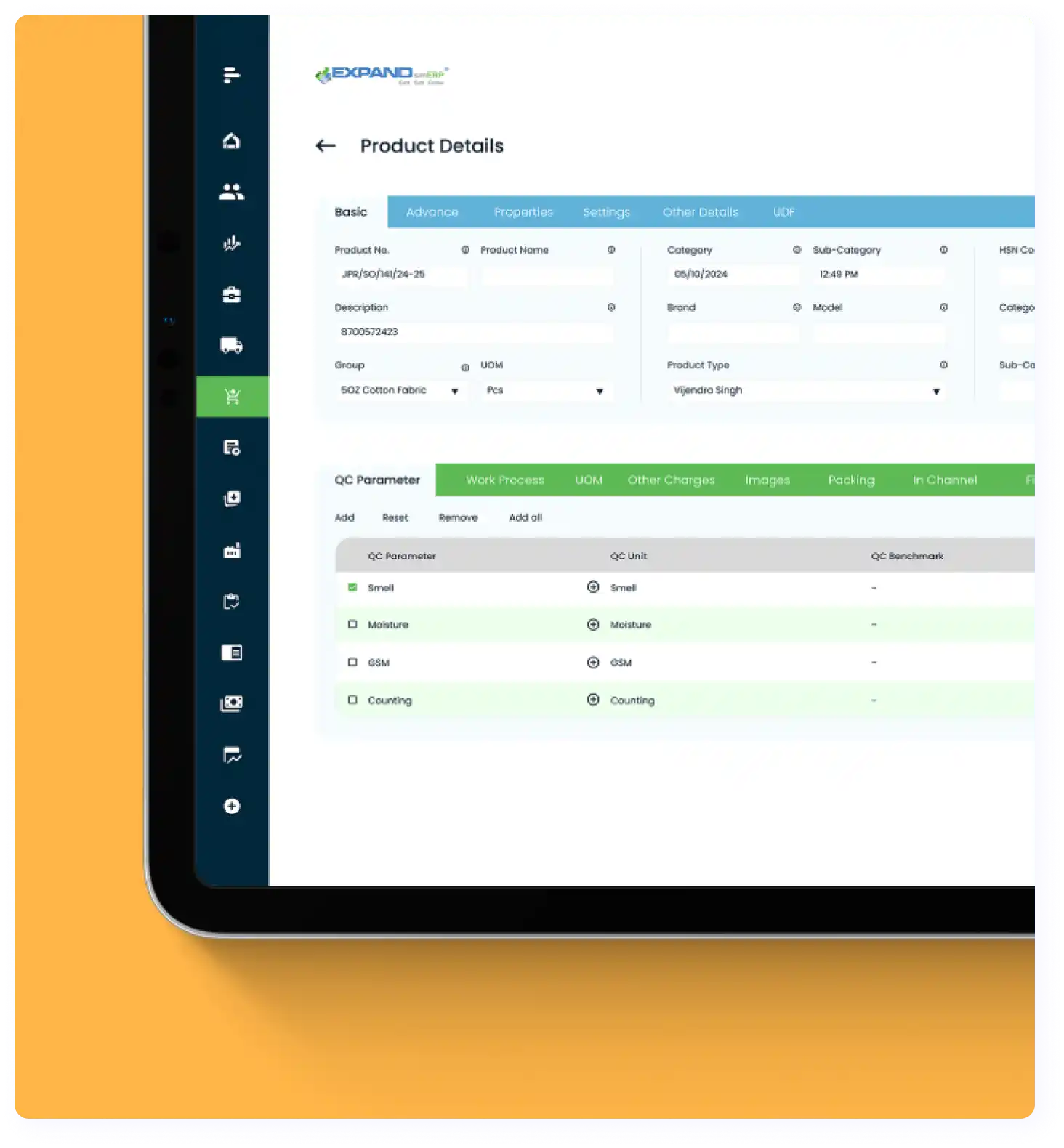

Quality Control

It helps manufacturers maintain quality standards by providing tools for inspection, testing, and compliance tracking.

Supply Chain Management

This module enables manufacturers to manage the entire supply chain, from procurement to distribution.

Production Planning

This module provides manufacturers with the ability to plan and optimize production schedules, streamline operations, reduce waste, and improve productivity.

Logistics for Manufacturing Industry

It helps manufacturers manage the flow of goods and information within the supply chain, reduce lead times, lower transportation costs, and improve delivery performance.

Procurement For Manufacturing Industry

It helps manufacturers optimize their procurement processes, reduce costs, improve supplier relationships, and ensure the timely availability of materials and supplies.

The best ERP software used in manufacturing industry comes with a range of features and functionalities designed to support various aspects of the manufacturing process. Here are some key features of ERP systems for manufacturing industry:

ERP software enables you to track inventory levels, manage stock movements, and automate reorder points. This ensures that you have the right materials at the right time to meet production schedules

This system provides financial management tools to ensure that manufacturers can manage financial operations effectively.

It enables businesses to manage production planning and scheduling effectively. This includes forecasting, capacity planning, material requirements planning (MRP), and scheduling.

ERP systems for manufacturing company include tools for quality management such as inspection, testing, and compliance tracking to meet quality standards and reduce the likelihood of defects.

It also enables manufacturers to manage shop floor operations that result in real-time visibility into the manufacturing process and helps to optimize production.

ERP systems enable manufacturers to manage the entire supply chain, from procurement to distribution.

Manufacturing process management software provides advanced reporting and analytics tools that enable manufacturers to gain insights into their operations.

It creates an interconnected network of various departments for effective communication and smooth workflow.

It's crucial to take a number of factors into account while selecting the right software in 2023. Assess your company's unique demands and objectives first. Look for a ERP platform that can improve manufacturing operations' efficiency by streamlining production procedures. Secondly, consider the features and functionalities of the program, such as inventory management, supply chain integration, and real-time reporting. Make sure that it complies with your business needs. Additionally, search for a comprehensive ERP system that provides user-friendly navigation and interfaces. A seamless connection between several departments or systems requires strong integration capabilities. Last but not least, be sure the provider has success working with the manufacturing sector. Choose Expand ERP, a robust ERP software system made especially for Indian companies that offers all these functions and helps you grow your business.

Enhance efficiency, optimize resources, and improve accuracy with ERP for production. Take control of your production planning with real-time data and automation.

Expand ERP is a powerful solution designed to streamline manufacturing operations, optimize production processes, and enhance overall efficiency with real-time insights.

Define Bill of material before production for proper procurement planning and material requirement planning. Get complete visibility of stock availability and change raw material with alternate material for specific batches of production.

Generate process for every stage of production as defined with the finished product. Define due dates for every process, outsource the process, and manage job work inventory and status. Define worker, machine, and downtime details for effective tracking and reporting. Get system alerts on.

Eliminates the hassle of manually preparing documents in Word editor and helps you complete quotation, and invoice documents five times faster. Instead of entering the same information over and over again, enter information in only one place. That makes you less likely to make costly mistakes.

In a typical scenario without ERP, every person manages 100s of spreadsheets. Once the data crosses over a few 100 rows and columns it becomes extremely time-consuming. Further to track the updated version and sharing of the spreadsheet is a nightmare and unsecured. Expand ERP gives all necessary reports with a click and can be exported to spreadsheets for further analysis.

ERP gives instant information on the status of orders and allows production to plan for material based on order position. The system can alert on pricing, credit limit and various other checks that will require enormous time to verify and hence will delay in order processing. Avoid delays in shipment and become more efficient.

If the business is not aware of its outstanding in the market or not properly managing its creditors, the bottom line is bound to be affected. ExpandERP ensures that there is no excess invoicing by Sales to meet numbers. The system sends automated reminders to customers for payment and also sends ledger details to sales reps for follow-up. This basic automation saves 20% time for business owners.

The fast pace of digitisation is bringing extra effort for every business to keep its data in proper order to meet all compliances. ExpandERP gives all necessary reporting for GST monthly uploads and purchase reconciliation.

Industry 4.0 brings in a complete shift in how business is conducted. AI and machine learning is disrupting the most profitable businesses. History has repeatedly shown that survival and success are with those who accept change and improvise with the help of technology. It is highly recommended to become more process-driven and reduce human intervention to achieve higher productivity.

Expand ERP caters to a wide range of industries, providing tailored solutions to streamline operations, enhance efficiency, and drive business growth.

Handicraft

Leather

Steel

Chemical

Export

Manufacturing

We take pride in partnering with industry leaders and growing businesses, delivering powerful ERP solutions that transform their operations and maximize success.

Hear from our satisfied clients and explore real-world success stories showcasing how Expand ERP has helped businesses achieve efficiency, productivity, and growth

Why Choose us

Expand ERP is a powerful solution designed to streamline operations, enhance productivity, and drive profitability. With real-time insights, cost reduction, and improved collaboration, our ERP manufacturing module helps businesses make informed decisions and stay ahead of the competition.

Get answers to common questions about ERP systems for manufacturing. Learn how ERP streamlines operations, enhances efficiency, and supports business growth.

Yes, production tracking is one of the primary functions of an ERP system. It can track records and data to provide you with real-time visibility into the production process.

An ERP production system is designed to manage and optimize the production process in manufacturing companies. It can help manufacturers improve their operational efficiency, reduce costs, and enhance quality control by streamlining processes, improving data visibility, and enabling informed decision-making.

Implementing ERP software can benefit your business in several ways. It can streamline processes, provide real-time data visibility, optimize resource utilization, provide accurate forecasting, and improve quality control which results in improved productivity and reduced costs.

The major challenges of implementing ERP for production include inadequate flexibility, maintenance costs, resistance to change, and staying informed.

Manufacturers can ensure a successful ERP implementation by involving all stakeholders in the process, conducting thorough planning and testing, providing comprehensive training to employees, and continuously monitoring and evaluating the system's performance.

ERP plays a major role in improving the efficiency of the manufacturing process. It is designed to integrate and streamline all aspects of production which improves productivity and customer satisfaction.

Industries such as manufacturing, healthcare, hospitals, education, retail, construction, and food and beverage can benefit from the ERP system.

ERP system help businesses make better decisions by providing real-time visibility into inventory data. It can automate operations, and control finances and logistics from a singular system which increases accuracy and efficiency.

Yes, ERP can help with supply chain management by making the process more scalable, efficient, and easy to manage.

An ERP system ensures that all products meet the desired quality standards by defining quality control processes, tracking quality-related data, and conducting quality inspections and tests. This process leads to improving the quality of the products.

Yes. You can configure the ERP system to support the company's unique production processes, workflows, and business rules. You can make it fully customizable to fulfill the company’s goals and requirements.

Streamline Operations & Boost Efficiency

Enhance your manufacturing processes with powerful manufacturing management software. Gain real-time insights, automate workflows, and improve productivity. Book a Free Business Audit Today!

Call us : +91 9007026542

Email us : [email protected]

Visit us : 304, PS Continental, 83, 2/1, Topsia Rd, Topsia, Kolkata, West Bengal 700046

Hosted on Certified Data Centers for Highest Level of Data Protection and Reliability.