Request for Callback

Fill out this form to download.

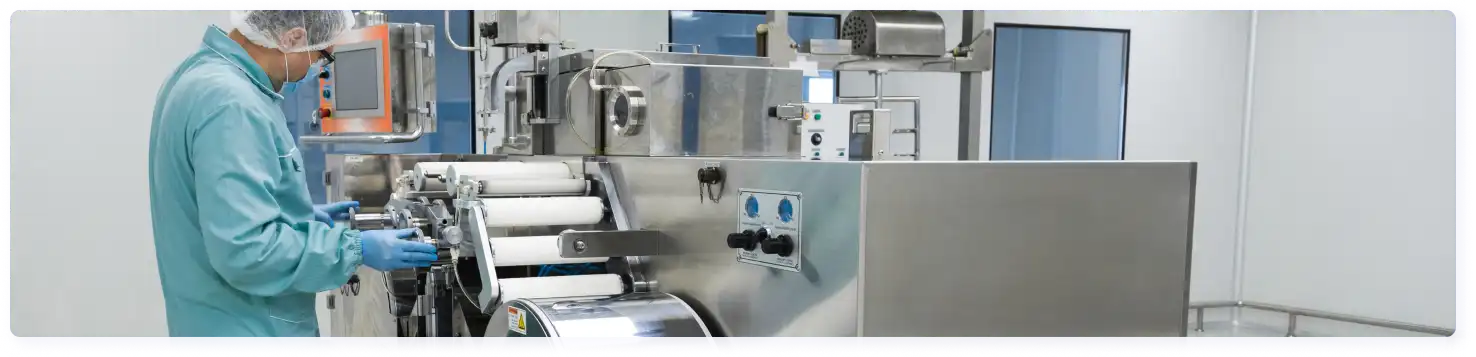

Efficiently track and manage QC parameters for every batch or lot produced

Managing various grades of plastic leads to production complexities and inefficiencies

Fluctuating material prices and sourcing challenges affect cost and reliability

Ensuring uniformity across batches is difficult, leading to potential quality issues

Inefficiencies in machinery, energy and labor increase production costs

Holding too much stock ties up capital, while too little can halt production

A recent study reveals that nearly 30% of plastic manufacturers experience significant production downtime, affecting overall efficiency and output

A unique and powerful software suite to transform the way you work

Gain real-time monitoring and track raw material usage and machinery status

Take a proactive role in tracking and moving inventory with characteristics that limit shelf life

Effortlessly manage BOMs with version control and easy modifications for production orders

Get real-time inventory tracking, enabling businesses to monitor stock levels across locations

Automates the tracking process and minimizes the risk of costly errors associated with the misidentification of goods

Take a personalized tour or let our expert know how we can best address your needs.

Get customizable reports and dashboards to meet the needs of the plastic and track performance metrics in real-time

Ensure management of various plastic grades, ensuring each type is processed according to its specific properties

Detailed tracking of QC parameters for each batch produced, ensuring consistent plastic product quality

Effortlessly identify cost-saving opportunities, reduce waste and optimize production schedules to reduce operating costs

Identify slow-moving items to prevent excess stock and optimize warehouse space and capital.

A powerful solution designed to solve your toughest challenges while unlocking strategic advantages to scale your business efficiently.

Join Our Happy UsersThese leading companies achieved remarkable ROI with minimal ERP investments.

Hosted on Certified Data Centers for Highest Level of Data Protection and Reliability.