Request for Callback

Fill out this form to download.

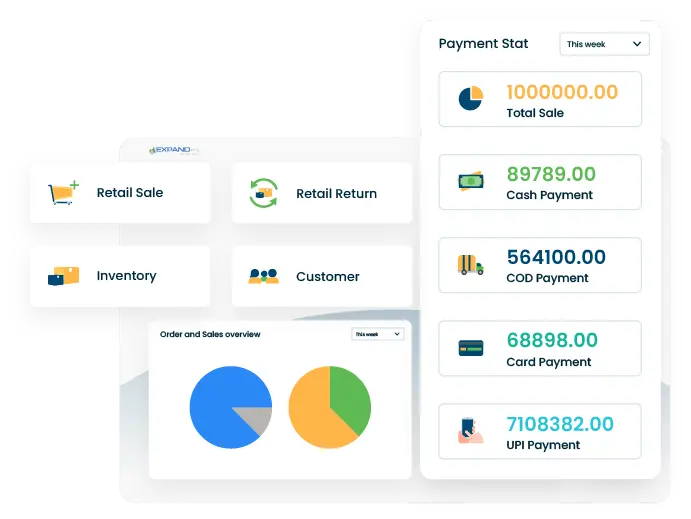

Transform your production and inventory by capturing realtime movement through mobile app and one click reports.

Capture instantly the inward, outward excess consumption based on listing, BOM and MRP this can save you a huge amount of time and bring full control over your production and eliminating your dependency on manual report that maybe incorrect.

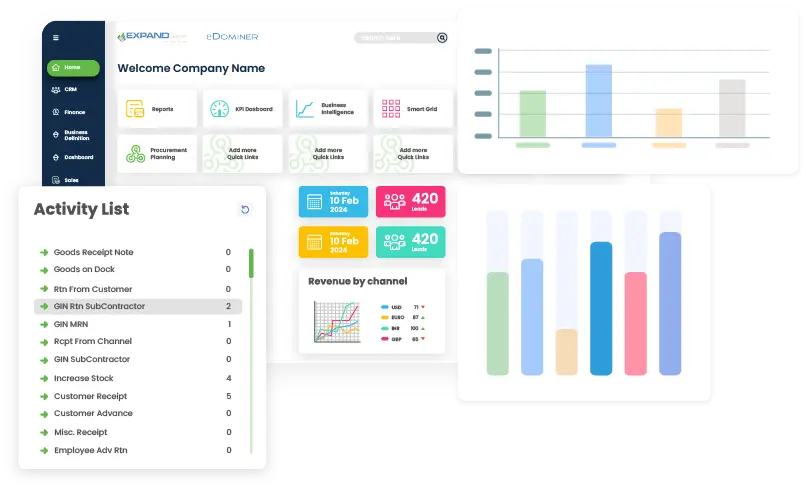

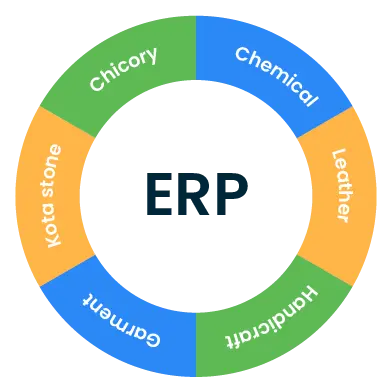

ERP is a comprehensive, scalable and customizable enterprise resource planning system that offers a transformation for manufacturing industry from the traditional software. In today’s hostile business environment, it is essential to be prepared to face a competitive world. ERP offers solution that enables manufacturing companies to compete in the prevailing market. A better management of your manufacturing processes transform the supply chain to achieve production plan with your sales plan, finance and customers.

Our ERP simplifies subcontracting activities by facilitating precise job scheduling, ensuring meticulous planning and coordination. It enables accurate progress tracking and documentation, promoting management transparency for timely project completion.

Material Requirements Planning (MRP) in Expand is one of the key functionalities that helps plan and manage the materials needed for the ongoing production of the Orders. MRP helps in optimizing inventory levels, ensuring timely availability of materials, generating Indents for the Purchase team, and increasing overall production efficiency.

Strategically utilise outsourcing as a cost-saving measure, choosing to procure goods from companies with comparative advantages. Manage subcontractors efficiently using Expand smERP's Jobwork feature, allowing the definition of jobs with multiple processes for seamless production oversight.

Efficiently manage Bill of Materials (BOM) with Expand smERP by seamlessly copying standard BOMs to production orders, allowing easy modification if needed. The system supports Measurement formulas for accurate consumption calculations and accommodates negative quantities on BOM lines, facilitating the handling of by- products in the production process.

Quality is the product's ability to meet customer expectations. It requires defining specific parameters for both raw materials and finished goods. Achieving and surpassing these benchmarks ensures customer satisfaction and establishes the product as of commendable quality.

The Job Card system streamlines and documents key production activities, offering crucial details for effective planning, execution, and ongoing monitoring. It acts as a central tool, ensuring organized and efficient processes, ultimately boosting productivity and informed decision-making.

Hosted on Certified Data Centers for Highest Level of Data Protection and Reliability.