Request for Callback

Fill out this form to download.

Boost efficiency and streamline operations with the best ERP software for the chemical manufacturing industry. Optimize processes, ensure compliance, and drive productivity effortlessly.

7,436+

Valued Clients

95%

Client Retention

90%

Tax Calculation

97%

Client Satisfaction

Streamline Operations and Boost Efficiency

In the highly regulated and complex chemical manufacturing industry, operational efficiency is key to staying competitive. Expand smERP’s ERP software offers powerful solutions designed to streamline processes, enhance productivity, and ensure full regulatory compliance.

Thank you for your interest in Expand smERP. Our team will reach out to you soon to schedule your personalized demo.

Book Your Free Demo Now!

Fill out this form to know your offer.

An ERP system is highly necessary in the chemical production sector. Producers in this industry encounter several difficulties, such as strict government rules, ongoing research and development, and safety standards. Additionally, companies also face challenges including high fuel prices, rising logistical costs, high operating costs, high electricity rates, and maintenance costs. All these situations make an erp chemical software highly necessary in the chemical industry.

Implementing ERP software for export documentation allows chemical manufacturers to reorganize their business processes, boost productivity, assure compliance, and get over the particular difficulties specific to their sector. Moreover, ERP software inventory management can also help you manage all inventory related operations smoothly.

The quantity needed for additives can vary significantly in chemical manufacturing standards. Even small adjustments in the amounts of additives used during a batch process can make a noticeable difference in the final product. An ERP system can automatically handle unit-of-measure conversions for various stock-keeping units (SKUs) to make this procedure simpler.

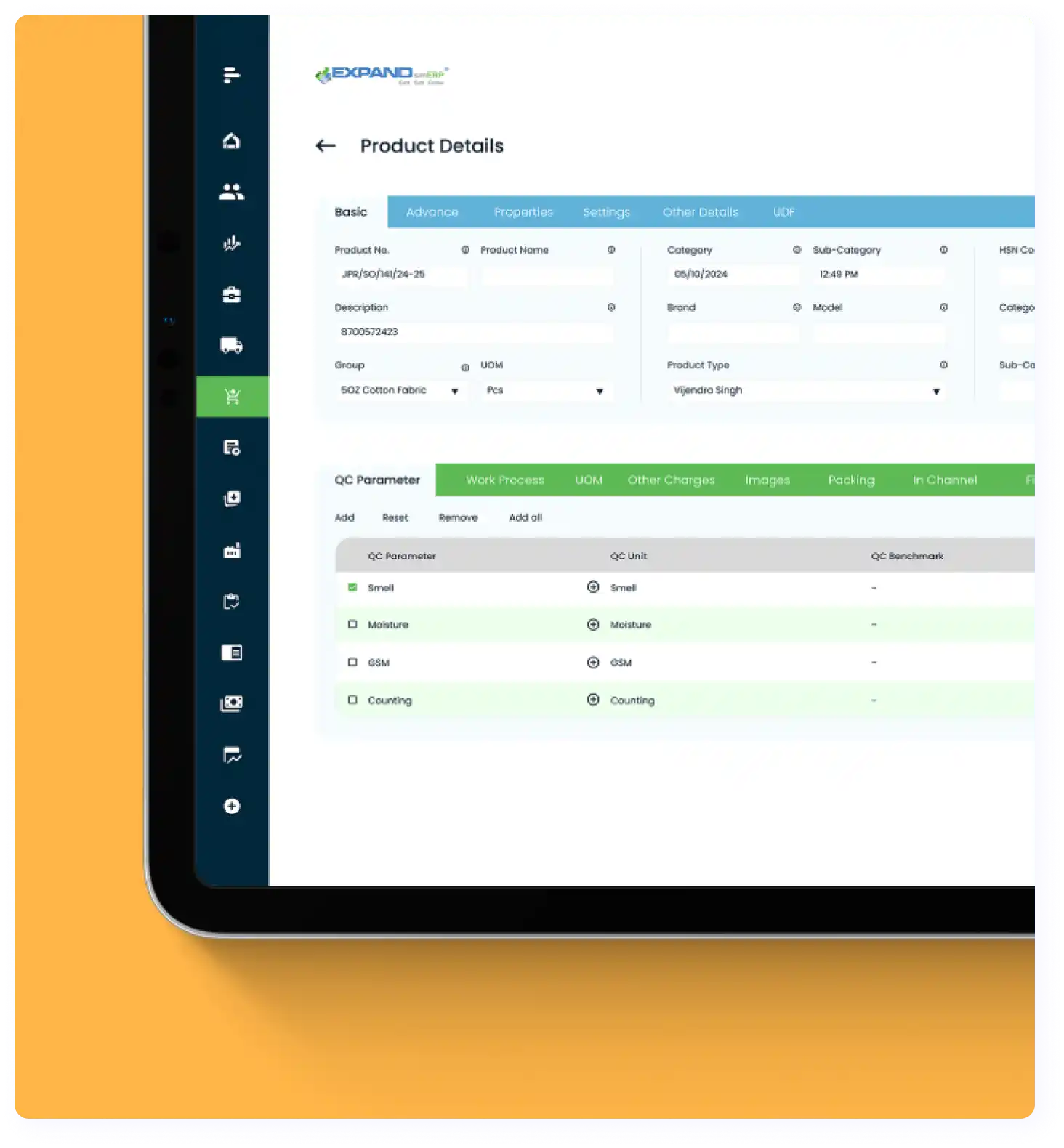

Quality control plays an important role due to the unpredictability of raw materials, the complexity of the production process, and the severe repercussions of regulatory non-compliance. ERP for chemical manufacturers can ensure that their goods satisfy both customer expectations and legal requirements by using a cloud erp system for chemical manufacturing.

Manufacturers have an important duty to comply with numerous national and international rules. ERP systems provide Document Management tools and integration with top Safety Data Sheet (SDS) authoring solutions to streamline compliance processes. As a result, businesses may rapidly produce the paperwork and ensure they comply with the legal requirements.

Chemical formulations can be challenging since they sometimes involve complicated mixtures of different additives and materials. These formulations may have multiple levels of hierarchy, with different components contributing to the final product's properties. An ERP system allows for the calculation of unique physical properties for specific products to improve product performance.

Chemical manufacturers may also face difficulties with managing concentrated additives, their potencies, strengths, and necessary dilutions. The batch production and formulation processes get even more complicated as a result of the diversity of raw materials. However, it can be reduced by integrating reliable formulation and batch production procedures inside an ERP system.

The production and handling of hazardous chemicals within a plant environment carry inherent safety risks for workers. The system library of chemical production software is built with strict safety rules to reduce these risks. These protocols are then incorporated into the specifications for each task.

While some chemicals may be highly valuable and need specialized storage facilities to maintain product quality and security, others may be susceptible to elements like temperature and humidity. Setting up location rules within an ERP system for storing particular product types is crucial to meet these needs so that chemicals are stored properly to maintain their integrity.

The production procedures used to make different chemicals can have a big impact on the environment, releasing pollutants into the air and water, emitting greenhouse gases, and producing waste material. Using an ERP solution the outputs of these processes can be tracked and monitored through data collecting and quality checks.

The chemical sector operates in a difficult environment that calls for specialized functionality and adaptability to remain competitive. Hence, it is now crucial for chemical firms to implement the best ERP software in India due to the complexity of chemical production. By doing so, you can improve efficiency, streamline workflow management, and improve overall operations.

Our one-of-a-kind ERP for manufacturing industry is specifically designed to address the needs of the chemical sector, giving companies the tools they need to successfully navigate shiftingmarket conditions and experience sustained growth.

So, if you are looking forward to streamlining your business process, then choose our ERP for production and manufacturing.

Unlock the full potential of your chemical manufacturing process with our specialized ERP solutions. Improve efficiency and compliance effortlessly!

Try Free Demo!

Accelerates the time to market for new goods and streamlines the product development process.

Gives real-time insights into capacity, resources, and demand, enabling them to scale up production quickly.

Offers robust quality management features that help ensure consistent and high-quality products.

It offers accurate and comprehensive cost tracking and analysis capabilities.

Track and manage compliance-related duties to stay compliant with industry standards.

Provides real-time inventory management, tracking raw materials, and finished goods.

It offers advanced planning and scheduling features that optimize production schedules, and material requirements.

Digitize and automate warehouse operations, which removes the need for paper-based records.

Our chemical manufacturing ERP software is designed to offer unmatched efficiency, accuracy, and scalability, making it the top choice for industry leaders.

Expand smERP beats competitors in terms of efficiency and productivity by enabling users to complete quotation and invoice documents five times faster.

Our technology generates all relevant reports with a single click, saving you up to 30% of your time when compared to traditional techniques.

What distinguishes Expand smERP is its ability to quickly advise users on crucial factors such as pricing, credit restrictions, and other necessary checks.

The system's automated reminders to customers for payment, coupled with sending ledger details to sales representatives for follow-up, sets it apart.

The seamless integration of the software with GST and e-Waybill systems ensures compliance with the most recent regulatory standards.

Our best chemical ERP software easily integrates weighbridge systems, barcode scanning, and lot tracking to ensure accuracy from raw materials to finished goods.

Essential ERP Modules

Our ERP software for the chemical industry includes powerful modules designed to optimize various aspects of your operations. From inventory management to production tracking, these modules provide comprehensive solutions to ensure smooth and efficient workflows.

With the help of this module, businesses can create thorough financial reports, manage their budget, manage billing and invoicing, and even handle payroll processing.

It offers a centralized platform where businesses can keep track of crucial client data, including contact information, communication history, and transaction records.

With the help of this module, you can keep track of and manage raw material purchase orders, regulate expenses, and manage the timely delivery of products.

This module helps you keep track of your chemical stock, manage product quantities, and monitor stock movements to ensure efficient supply chain management.

You may handle and keep track of significant papers for your chemical business, like invoices, purchase orders, and shipping documents, with the help of a document tracking module.

This module manages the paperwork, customs laws, shipping logistics, and cargo tracking for both import and export operations, which helps in managing global trade procedures.

This module assists you in managing the manufacture of chemicals, including the tracking of raw materials, work-in-progress, and finished commodities.

Users get access to consolidated reporting at various levels, which is presented through interactive dashboards that are up to date.

The security measures implemented in the system are configurable based on role-level access, so that access to data is granted based on the user's role within the organization.

Improve your chemical production process with our easy-to-use ERP software. Streamline operations, boost efficiency, and stay compliant effortlessly!

Handicraft

Leather

Steel

Chemical

Export

Manufacturing

Why Choose Us?

Expand smERP provides a reliable and comprehensive ERP solution designed specifically for the chemical manufacturing industry. Our software streamlines your processes, enhances productivity, and ensures regulatory compliance, all while offering real-time insights for better decision-making.

Key Reasons to Choose Us:

An enterprise resource planning (ERP) system specifically created for chemical manufacturing enterprises is known as chemical ERP software. It offers industry-specific features and functions to regulate and streamline several processes involved in the manufacturing of chemicals.

ERP software has tools and functions that help chemical firms track compliance-related activities, manage documentation, and produce reports for regulatory bodies.

ERP software can link with lab systems, providing easy data exchange between the ERP system and quality control operations in the lab.

Yes. ERP software can be modified to fit the unique demands of chemical manufacturers, including workflow adaptation, the addition of industry-specific functions, and the incorporation of unique reporting and analytics, giving specialized business solutions.

Take the First Step Towards Efficiency

Request a free demo and receive a personalized business audit to enhance your chemical manufacturing process with ease.

Call us : +91 9007026542

Email us : [email protected]

Visit us : 304, PS Continental, 83, 2/1, Topsia Rd, Topsia, Kolkata, West Bengal 700046

Hosted on Certified Data Centers for Highest Level of Data Protection and Reliability.